Modern cleaning solutions have evolved significantly, and one innovation stands out: the bagless vacuum system that uses centrifugal force to trap particles. This approach, inspired by industrial separators, ensures consistent suction and efficiency.

Originally developed for sawmills and factories, this method was adapted for household use. It eliminates the need for bags while maintaining powerful performance. Key components like dual cyclones and frusto-conical designs work together to achieve airspeeds of over 200 mph.

Today, this groundbreaking approach is integrated into cordless models, offering convenience and reliability. Its impact on the vacuum cleaner industry is undeniable, setting new standards for performance and user experience.

Introduction to Dyson Cyclone Technology

The story behind Dyson’s breakthrough began with a simple observation in 1978. James Dyson, frustrated with traditional vacuums losing suction due to clogged bags, sought a better solution. His visit to Hill Leigh Ltd., a sawmill, introduced him to industrial cyclones. These devices used centrifugal force to separate dust and debris efficiently.

Inspired by this design, Dyson developed the G-Force prototype in 1983. This innovative model was exclusively launched in Japan, marking the first step toward revolutionizing home cleaning. By 1993, the DC01 became the first commercially successful Dyson vacuum cleaner, setting new standards for performance.

Over the years, the technology evolved with improved motors, batteries, and handheld designs. These advancements ensured that the cleaner could handle even the smallest particles without losing suction. Today, Dyson’s innovations continue to shape the industry, offering users unparalleled convenience and efficiency.

The History and Evolution of Cyclonic Technology

The journey of cyclonic separation began long before it became a household staple. Its origins trace back to the 19th century, where it was first used in industrial settings to improve safety and efficiency. Early applications included sawmills and flour mills, where cyclones helped control dust and prevent explosions.

By the early 20th century, cyclonic separation found its way into oil refineries and sewage plants. These industrial use cases demonstrated the effectiveness of cyclones in handling large volumes of particles. However, it wasn’t until the late 20th century that this technology was adapted for home cleaning.

From Industrial Use to Household Appliances

The transition from factories to homes was a significant leap. James Dyson, inspired by industrial cyclones, saw the potential to revolutionize cleaning. Over 15 years, he developed thousands of prototypes, refining the design to suit domestic needs.

One of the key challenges was miniaturizing the technology. Industrial cyclones were large and bulky, but Dyson’s team managed to create compact, efficient systems. This innovation eliminated the need for bags, offering a more convenient and cost-effective solution for households.

Dyson’s Breakthrough: The Dual Cyclone

The Dyson Dual Cyclone marked a turning point in cleaning technology. Introduced in 1993, the DC01 was the first commercially successful model. It featured two cyclones—one for larger particles and another for fine dust—ensuring consistent suction and performance.

Dr. Ricardo Gomiciaga played a crucial role in refining the physics behind the cyclones. His work helped optimize airflow and particle separation, making the company’s products even more efficient. Today, multi-cyclone systems like the Root Cyclone continue to set new standards in the industry.

For more insights into the development of this groundbreaking technology, explore this detailed resource.

How Does Dyson Cyclone Technology Work?

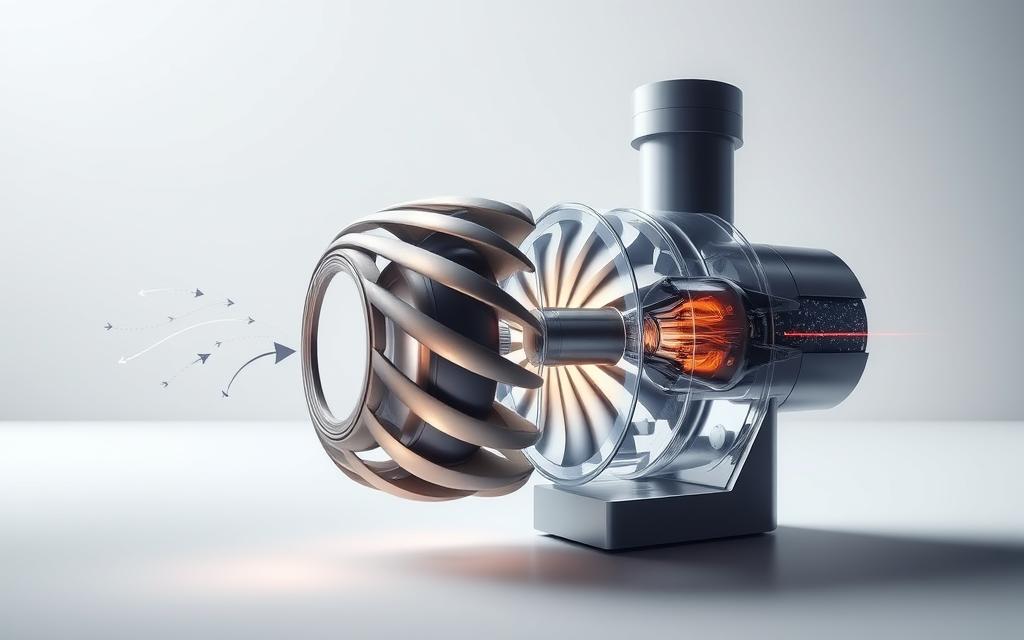

At the heart of advanced cleaning systems lies a powerful mechanism inspired by nature. This technology relies on centrifugal force to separate dust and debris from the air. By spinning air at high speeds, it creates a force that pushes particles outward, trapping them effectively.

The Science Behind Centrifugal Force

Centrifugal force mimics the dynamics of a tornado. When air spins rapidly, heavier particles are flung outward due to inertia. This principle is applied in cyclones, where air rotates at speeds exceeding 200 mph. The outer cyclone handles larger debris, while the inner cyclone reaches up to 924 mph for fine dust removal.

The Dual Cyclone Process Step-by-Step

The dual cyclone system is a marvel of engineering. Here’s how it works:

- Step 1: Dirty air enters the outer cyclone. Larger particles are ejected into the collection bin.

- Step 2: Smaller particles spiral into the inner cyclone. This stage ensures micro-dust is captured efficiently.

- Step 3: Clean air exits through HEPA filters, reducing allergens and improving indoor air quality.

Transparent bins allow users to observe the process, showcasing the effectiveness of the system. This precision engineering is detailed in Dyson’s “cyclonic Bible” spreadsheet, ensuring optimal performance.

| Component | Speed | Function |

|---|---|---|

| Outer Cyclone | 200 mph | Removes large debris |

| Inner Cyclone | 924 mph | Captures fine dust |

Benefits of Dyson Cyclone Technology

Home cleaning has been transformed by advanced systems that deliver unmatched performance. These innovations offer significant advantages, from consistent suction to improved health benefits. Let’s explore the key features that make this technology a game-changer.

Improved Suction and Efficiency

One of the standout features is its ability to maintain 100% suction power. Unlike traditional models that lose up to 50% efficiency, this system prevents clogging. Cyclones generate forces up to 79,000g, ensuring even the finest dust is captured without compromise.

Bagless Design and Cost Savings

The bagless design eliminates the need for disposable bags, saving users over $200 annually. Reusable bins and long-lasting filters reduce maintenance costs. With spare parts designed for durability, this approach is both eco-friendly and economical.

Health and Allergen Control

Advanced HEPA filters trap 99.97% of particles as small as 0.3 microns. This includes allergens like pollen, dust mites, and bacteria. For households prioritizing health, this technology ensures cleaner air and a safer environment.

With over 50% market share in the UK and growing dominance in the U.S., the Dyson vacuum continues to set industry standards. Its performance and convenience make it a top choice for modern homes.

Conclusion: Why Dyson Cyclone Technology Matters

Cleaning appliances have reached new heights, thanks to innovative engineering. Cyclonic systems have revolutionized vacuum design, offering consistent performance and user convenience. Dyson’s commitment to R&D, including a £50M investment in 2005, has driven this evolution.

Future advancements may include self-repairing vacuums and robotics, further enhancing efficiency. For modern households, cyclonic tech delivers significant benefits—improved air quality, cost savings, and long-term reliability.

Prioritizing this technology ensures cleaner homes and better health. As the industry evolves, cyclonic systems will remain a cornerstone of effective cleaning solutions.